Welcome to Ace Forming – Specialist in formed precision metal components

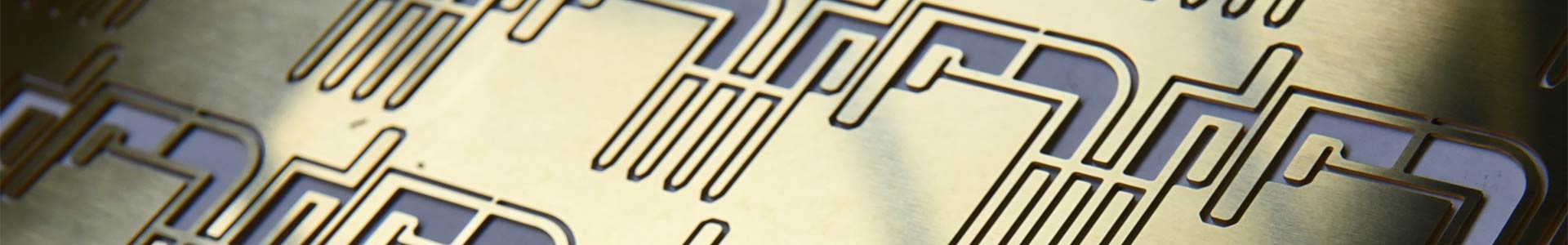

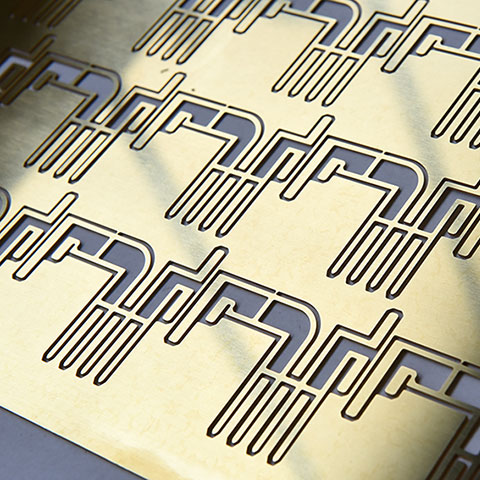

Ace Forming is a critical partner in the development of formed precision metal components utilising chemically etched, pressed, wire eroded, water jet and laser cut blanks.

Our unrivalled technical expertise, ability to solve complex manufacturing issues and fast lead times have seen us supply into a host of high profile customers in automotive, aerospace, electronics, general engineering, medical and telecommunications sectors.

Located in the heart of the West Midlands, we are able to work in all types of metal and exotic alloy and can manufacture parts from 0.01mm to 6mm thick in volumes from as small as 1 offs to batches of 10,000 components.

At Ace Forming, we pride ourselves on continuous improvement and this is reflected in the personal development opportunities we offer our staff and investment in new capacity and capability, typified by the launch of our dedicated wiring loom cell.