Sectors

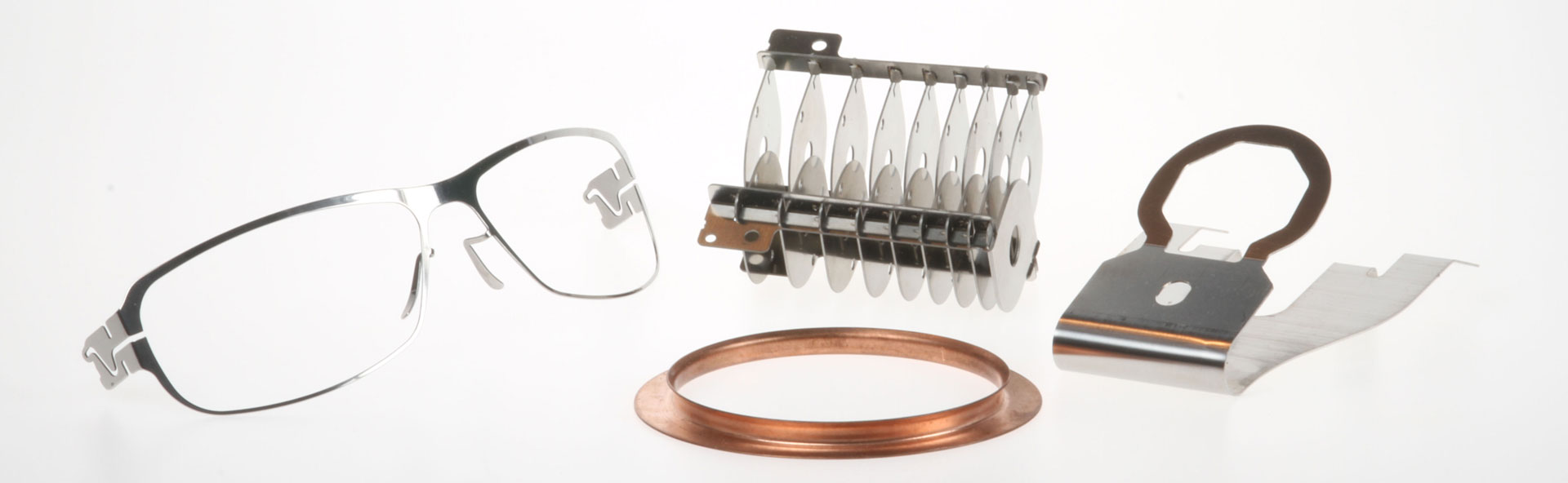

ACE Forming’s ability to problem solve and turn initial drawings into reality has seen it work for clients across every industry imaginable.

Our formed parts can be found in Formula 1 cars, mobile phone masts, smoke alarms and even airplanes.

Despite the difference in end user, the client receives the same level of customer service, attention to detail, traceable quality and design innovation.

The knowledge and understanding of our people is crucial, with many of the team being with us since we launched in 2003.

This means they understand our philosophy and have significant experience of taking new parts into production, often stripping back and evolving the design so we deliver the required performance.

Another example of the Ace Forming difference.

Sectors we work in:

A critical partner to the aerospace and defence sector, Ace Forming has developed a proven track record for delivering fast lead times, innovative engineering solutions and components that can perform in extreme environments.

These three attributes – combined with core lean manufacturing principles – has seen the company’s products used in the development of numerous aircraft platforms.

Components we supply:

- Actuators

- Bus bars for power components

- Contacts/ terminals

- Control gear components

- Instrument panel

- Interior lighting components

- Leadframes for electronic devices

- Mounting brackets

- RFI shielding

- Springs

Ace Forming plays a significant role in the automotive industry’s ability to bring new components to market, working with a wide number of precision stamping companies to provide fast, accurate and cost effective prototypes.

We have also supplied parts up to pre-production whilst the production tooling is still being manufactured, providing a unique and critical link within the supply chain.

Our expertise spans:

- Actuators

- Battery contacts

- Bus bars for lighting circuits, power components, fuel circuits, latching devices

- Connector assemblies

- Contacts/terminals

- Diaphragm springs

- Leadframes for electronic devices

- Pipe clips

- RFI Shielding

- Small wiring looms

- Under bonnet brackets

Investment in a new wiring loom facility and constant updating of our modern manufacturing facility in the West Midlands has given us the capabilities and capacity to bring our precision component expertise to more than 20 different sectors.

Traditional engineering principles and expertise in design for manufacture has seen us become a partner for companies involved across all aspects of high value engineering.

- Assemblies

- Battery contacts

- Clips

- Formed brackets

- Mounting plates

- Precision washers

- Spacers

- Springs

Reducing emissions and introducing new green technology is a major growth area for UK industry and Ace Forming is at the forefront of providing precision components as prototypes or in small volume runs.

- Bus bars

- Gaskets

- Slip rings

- Small wiring looms

Electronics / Telecommunications

Electronics / Telecommunications

Within the fast paced world of telecommunications, Ace Forming works with development engineers to produce quick, accurate and inexpensive prototypes and production components.

This ranges from development micro connectors to high volume mounting brackets for base stations. In this sector, speed of response is everything.

- Antennas

- Connectors/terminals

- Heat sinks

- Mounting brackets/ bus bars for base stations

- RFI shielding

- RFI finger strip

- Screen cans

- Small wiring looms